Major Services We Provide

Steel Structure Fabrication (CNC Plasma Cut)

Precision cutting and fabrication of columns, rafters, base plates, cleats, brackets, and purlins using CNC plasma machines for high-quality, accurate assembly.

On-Site Erection & Installation

Professional lifting, alignment, and bolting of all PEB components using skilled manpower and equipment.

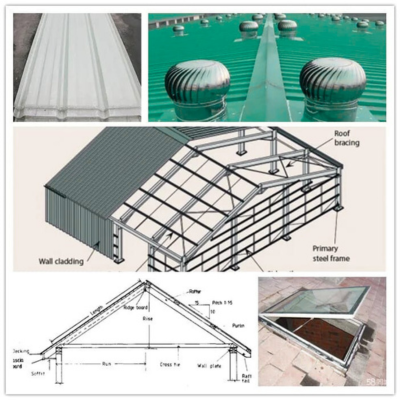

Roofing & Cladding Works

Fixing of metal sheets, PUF panels, translucent sheets, and wall coverings with waterproofing measures.

More Services

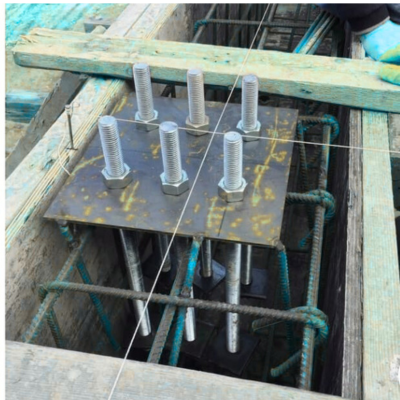

Anchor Bolt & Base Plate Alignment

Accurate placement and leveling of anchor bolts and base plates before structure erection for stability and fitment.

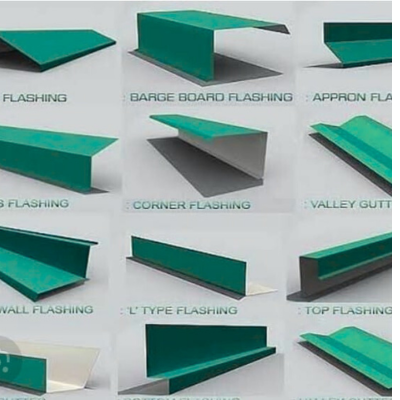

Ridge & Corner, Gutter Flashing Installation

Fitting of ridge covers, corner trims, and flashing to seal junctions and protect from weather leaks.

Z Purlin Installation

Accurate and strong Z purlin fixing to ensure reliable roof and wall support.

Ventilator & Louvers Installation

Mounting of turbo ventilators, ridge ventilators, and louvers for natural air circulation and heat control.

Complete civil work including site leveling,

Foundation excavation, PCC, RCC footings, pedestal casting, anchor bolt fixing, and backfilling—ensuring a strong and accurate base for PEB structures.

Frequently Asked Questions

A PEB is a factory-fabricated steel structure designed for quick assembly on-site, offering faster, economical, and durable construction compared to conventional buildings.

Depending on size and complexity, most PEB projects are completed within 6 to 12 weeks, including design, fabrication, and erection.

Yes. PEBs are fully customizable — from dimensions and roof type to mezzanine floors, wall cladding, and crane provisions.

Cost varies based on location, design load, materials, and specifications. We offer cost-effective pricing after reviewing your specific needs.

Absolutely. Properly designed PEBs follow IS or international codes and can last 50+ years with minimal maintenance.