When planning a new construction project, one of the most important decisions you’ll make is choosing the type of building structure. Traditionally, most buildings have been constructed using conventional methods like RCC (Reinforced Cement Concrete) or brick-and-mortar systems. However, in recent years, Pre-Engineered Buildings (PEB) have gained massive popularity, especially for industrial, commercial, and even institutional projects. So, what makes PEBs stand out, and is it time to shift from traditional construction? Let’s explore.

1. What is a Traditional Steel Structure?

Traditional steel structures are usually fabricated and erected on-site using materials like I-beams, channels, pipes, and angles that are readily available in the market. These structures are typically built by local welders without detailed structural calculations, engineering design, or alignment. The process is labor-intensive, and quality depends entirely on the skills and judgment of the workforce.

Key Features of Traditional Steel Structures:

- No structural drawings or design parameters in many cases

- On-site welding and fabrication with poor alignment and finishing

- Built by untrained or semi-skilled welders

- Time-consuming and labor-heavy

- Inconsistent quality and shorter life span

- More steel used unnecessarily where not needed, due to lack of optimization

- Final cost and quality highly dependent on the contractor’s approach and materials used

In general, there is a misconception among the public that traditional structures are cheaper. But in reality, if proper design and engineering calculations are followed, traditional structures tend to consume 25% more steel than PEBs, making them costlier.

However, in many actual cases, contractors use 35–40% less steel than required by proper engineering parameters to reduce costs and win the job. This compromises safety, durability, and structural performance. The structure is often built merely to “look complete” rather than being genuinely engineered.

This misleading practice gives the false perception that traditional construction is cheaper. In truth, when both systems are fairly compared based on sound architectural drawings, proper design, and material standards, PEB is the more economical, safer, and technically sound option.

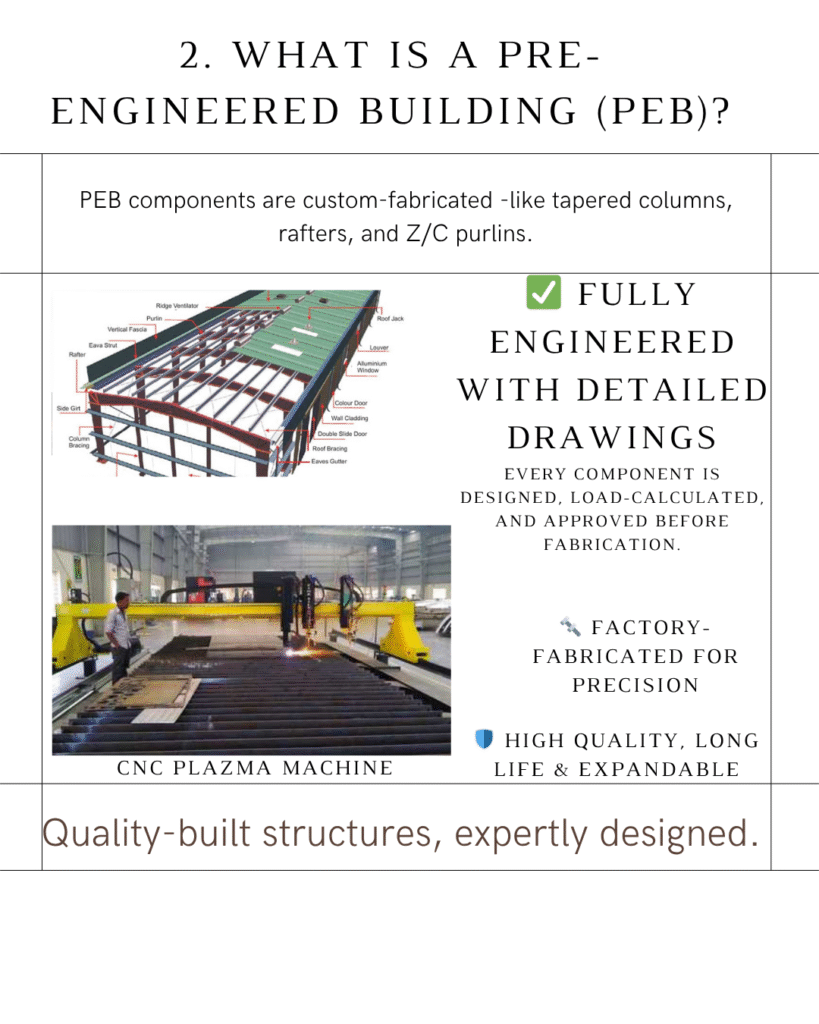

2. What is a Pre-Engineered Building (PEB)?

PEBs are fully engineered steel structures where each component is designed, calculated, and manufactured in a controlled factory environment. Fabrication is done using CNC plasma machines, automated welding systems, and strict quality control measures. All elements are approved by experts based on industry codes and structural formulas. These components are then transported to the site and assembled using bolts with minimal or no on-site welding.

Key Features of PEBs:

- Fabrication with CNC plasma and automatic welding machines

- All designs approved by structural experts

- Built in-house with strict quality testing

- Transported and erected using bolts (no on-site welding)

- Fast, efficient, and consistent

- Less steel used due to design efficiency (steel is reduced where less load is present)

3. Speed of Construction

PEB Advantage: PEB structures are significantly faster to erect as most work is done in the factory. On-site work is limited to bolting and assembly, drastically reducing construction time.

Traditional Steel Construction: Fabrication is done on-site, which involves delays , weather, and material handling.

Result: Traditional vs. PEB Structures: What’s Best -PEB projects can be completed 30–50% faster.

4. Cost Efficiency

PEB Advantage: PEBs save on labor, reduce waste, and shorten project duration. Optimized design and lighter materials also reduce structural costs.

Traditional Steel Construction: Even when properly designed, traditional structures often cost 25% more due to inefficient material use and longer timelines. But in many cases, contractors reduce steel usage by up to 40% to make the structure appear cheaper, which compromises integrity.

Result: Traditional vs. PEB Structures: PEB is not only cheaper but also more reliable and durable when both are compared using standard parameters.

5. Design Flexibility & Aesthetic Appeal

PEB Advantage: Modular and flexible design options allow for aesthetic elements like skylights, canopies, mezzanines, and extensions.

Traditional Steel Construction: Changes in design after work begins are costly and difficult to implement.

Result: Traditional vs. PEB Structures: PEB offers more flexibility for future expansion and customization.

6. Quality Control & Safety

PEB Advantage: Fabricated using advanced machines with tight tolerances, ensuring precision and compliance with safety codes. All welds and materials are tested before delivery.

Traditional Steel Construction: Welding is done on-site by manual labor without standard testing. Quality varies and depends heavily on individual skill levels.

Result:Traditional vs. PEB Structures: What’s Best – PEB ensures far better safety, alignment, and durability.

7. Environmental Impact

PEB Advantage: Minimal site pollution, less material waste, and recyclable components make PEB a more sustainable option.

Traditional Construction: High on-site waste generation, excessive use of natural resources, and minimal recycling.

Result: Traditional vs. PEB Structures: What’s Best -PEB aligns better with green building standards.

8. Maintenance and Durability

PEB Advantage: PEB structures are treated to resist corrosion and last over 40 years with minimal maintenance.

Traditional Steel Construction: Susceptible to rust, poor finishing, and water damage. Requires frequent repairs and upkeep.

Result: Traditional vs. PEB Structures: What’s Best -PEB is a low-maintenance, long-life solution.

9. Applications

PEBs are ideal for:

- Warehouses

- Industrial Sheds

- Showrooms

- Schools & Institutions

- Commercial Buildings

- Banquet Halls & Auditoriums

Traditional steel structures are used for:

- Low-cost temporary setups

- Small storage or non-engineered spaces

- Areas where engineering oversight is not prioritized

10. When Should You Choose PEB?

Choose PEB when:

- You want faster project completion

- You want lower cost with higher quality

- You require large open spans with minimal columns

- You need future expansion options

- You want certified engineering and long life

Final Thoughts

While traditional steel structures still exist in remote or budget-constrained settings, the superior quality, speed, and durability of PEB make it the smarter choice for most modern applications.

Pre-Engineered Buildings (PEBs) not only deliver higher value but also eliminate the guesswork and inconsistencies found in conventional structures. The common belief that traditional structures are cheaper is based on shortcuts and misrepresentation, not actual engineering.

When both systems are designed and built with correct standards, PEB is clearly more economical, faster, and reliable.

Need help choosing the right solution? Contact Vananchal Eco PEB at our wave site today for a free expert consultation and cost-effective project proposal. Contact Nhttps://vanpeb.com/contact/ow:-

hi